15 Jan 2024

10 minutes to read

Resilient Design for Critical Infrastructure: Ensuring Reliability in Data Centres

To compliment our article on prime movers for power generation, this article looks at different fuel technologies coming to the market, that could be used for supplying power generation plant for Data Centres.

Renewable fuels are fuels produced from renewable resources. As global warming average temperatures increase year-on-year, the need to phase out fossil fuels is paramount. Renewables and Synthetic Fuels (e-fuels) currently face three overall obstacles; volumetric density improvements, costs and the need for secure & ethical supply chains. Following from news of the ‘renewable’ status of some fuels being claimed fraudulently, the US EPA has developed a RIN (Renewable Identification Number) code to track the production and distribution of such fuels.

Biofuels

Biofuels are any fuels produced from biomass and are usually biodegradable, cleaner burning and can be converted directly into liquid fuels. They are cost effective, renewable and nearly 100% CO2 neutral. Additionally, they are easy to transport and store whilst also being able to be used as replacement fuels without the need for new infrastructure.

Biofuels can be separated into 3 generations with first generation (1G) using food crops as its source, second generation (2G) using energy crops and food waste and third generation (3G) using microalgae - although this has mostly been abandoned now. Generally, despite 1G being less sustainable, it is more commonly used than 2G due to it’s cost-effectiveness and established processes. Bioethanol and biodiesel are the most common fuels which belong to 1G.

Conversion process

Biofuels can be converted by direct burning, decomposition, deconstruction and fermentation. The process of deconstruction uses two types; High and Low Temperature. High Temperature deconstruction uses 3 different processes; gasification, pyrolysis and hydro-thermal liquefication. Low Temperature deconstruction uses enzymatic hydrolysis; a process of breaking down feedstocks by enzymes or chemicals (biological catalysts) into intermediates. Each process is selected depending on the end aim of fuel to be produced and the resources available.

Biofuels in Europe & UK

Biodiesel is the largest liquid bio-fuel in Europe (10% of all bioenergy, 77.1% of all liquid biofuels) whilst bioethanol and biomethane come in 2nd and 3rd place respectively. Similar trends are followed by the UK but with biodiesel and bioethanol far ahead of the pack and biomethane at very similar (lower) levels to biopropane.

Hydrogen and Ammonia (NH3)

Hydrogen (H2) is a highly flammable odourless and colourless gas with very high energy density. It is color coded based on the resource fuel and process. H2 production process include gasification (natural gas reforming), electrolysis, renewable liquid reforming and fermentation. Green Hydrogen is defined as hydrogen produced by the electrolysis process using renewable electricity to split water atoms into hydrogen and oxygen by electrolyzers. Hydrogen can be delivered via pipeline, tube trailers and/or liquid tankers and can be compressed to 180bar for storage or transport (compared to 20-30bar in the production process). Concerns have been expressed about excessive H2 gas leaks but scientific modelling suggests that leakage rates of <1% can be achieved in new H2 infrastructures.

Ammonia is a colourless, pungent gas and is a medium to transport and store hydrogen in its liquid form. It can also be decomposed in destination to produce hydrogen and nitrogen or used as a fuel in internal combustion engines. There are two processes to produce Ammonia; the Haber-Bosch(HB) process - the main ammonia production method that involves high pressures and temperatures with GHG emissions – and Low-pressure electrolytic Ammonia (LPEA) - the green production method, by using green electricity to electrolyze water to obtain hydrogen and react with Nitrogen to result in ammonia.

Transportation and storage are the main barriers in the expansion of hydrogen economy. Liquid Ammonia is a more suitable way for the transportation of hydrogen as it has a higher energy density and much lower liquified pressure compared to liquid hydrogen.

Synthetic Fuels

Synthetic fuels are a type of fuel that can be produced from a variety of sources, including carbon dioxide, natural gas, coal, biogas, and biomass. The production process involves capturing carbon dioxide and using it as a raw material to produce e-gasoline, e-diesel, and substitute natural gas (e-methane) as well as e-methanol. This is achieved through combining the CO2 with H2 that is produced from renewable sources. With the help of electricity from renewable sources to power the whole process. Synthetic fuels are also known as carbon-neutral fuels, as their manufacturing process captures CO₂, thereby making a significant contribution to limiting global warming .

Electrical efficiency and price comparisons of future fuels

The electrical efficiency varies a lot depending on the technology used (i.e. whether it’s an engine, turbine or fuel cell). However, if the waste heat from combustion is utilised, i.e. through CHP designs (Combined Heat Power), fuel utilisation could reach up to 85%. Burners, injector nozzles and combustion chambers might need to be adjusted for fuel flexibility of certain fuels like ethanol. A positive aspect however is that modifications can be minimal for certain fuels like Dimethyl Ether (DME – a synthetic alternative to diesel).

The specific energy of H2 is more than 3 times that of diesel but energy density of H2 liquid is less than one third of diesel. Energy density of natural gas (0.036 MJ/l) in ambient temperature is more than 3 times of H2 in gaseous form (0.011 MJ/l).

The price of fuels varies by region and political factors. Price of natural gas varied between $2 and $50 per BTU in the past 40 years. However, the prices of biodiesel and propane have been consistently higher than diesel over the past few decades. Compressed Natural Gas (CNG) had the cheapest price historically whilst ethanol and diesel had similar price patterns the last few decades. Meanwhile, e-kerosene and hydrogen are expected to drop in price in the US and Europe due to developing production plants.

Emissions of fuels

NOx and CO emissions are the most pertinent pollutants from natural gas generators. Comparing natural gas with other renewable fuels; Ammonia has higher NOx emissions than natural gas whereas methanol and ethanol have lower NOx, CO2 and particulate matter.

Hydrogen fuel cells are the ‘greenest’ provided the hydrogen is made from renewable electricity means. However, hydrogen burning turbines produce more NOx emissions (up to 3 times higher) than gas due to the higher combustion temperatures.

In addition it’s important to consider that whilst biofuels may produce less upfront emissions, their lifecycle emissions could amount to higher levels overall.

Natural Gas

Natural Gas is primarily made up of Methane (CH4) and has lower emissions than diesel or coal. Whilst less polluting it can never reach carbon-zero status while using non-RNG sources. It can be extracted from oil wells or coal beds (non-renewables) or from landfills, sewage or other waste (renewables).

Transportation of natural gas happens through pipelines or vehicular means (ships, lorries etc.). However with vehicles it’s harder to transport due to the need for it to be in liquid form which requires cryogenic conditions. Storage methods involve tanks, underground caverns, aquifers and salt caverns.

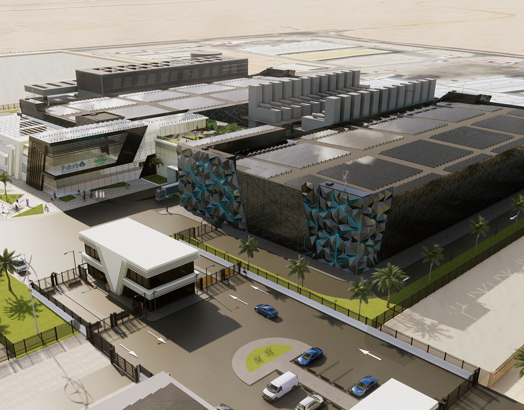

A number of data centres are using natural gas powered onsite prime power generation in certain grid constrained areas. Although this is an in interim solution, based on business need, the ability to migrate this plant to future biofuels or synthetic fuels to decarbonise once a sustainable supply chain for this fuel is in place.

This article, along with the supporting article on prime movers, formed part of REDs research and development of off-grid microgrid solutions as an alternative power source for grid constrained areas. Further information on microgrids will be published as part of the wider series of articles on Resilient Design for Critical Infrastructure: Ensuring Reliability in Data Centres.

Latest Insights

View all insights